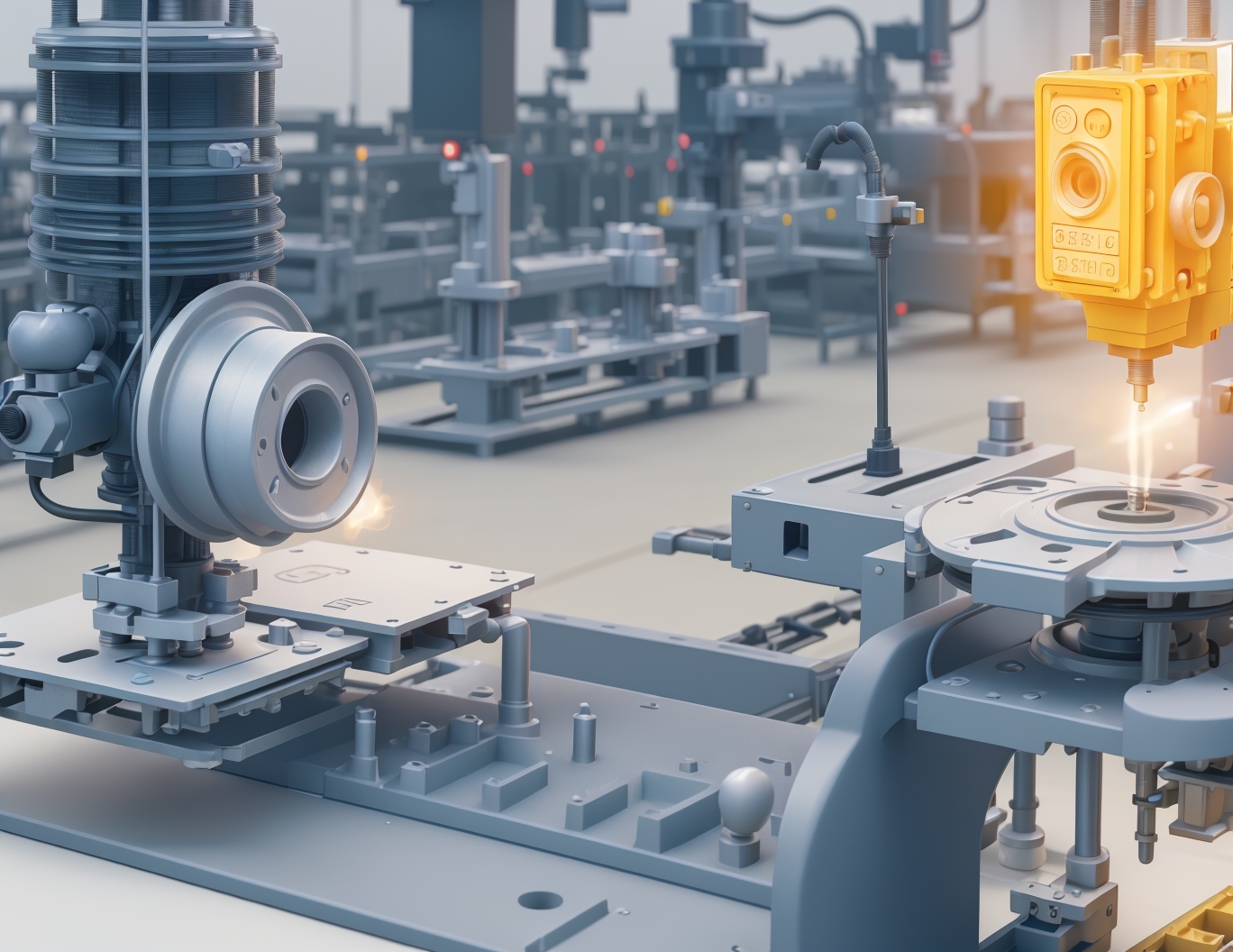

The Role of 3D Printing in Automating Manufacturing Processes

The Role of 3D Printing in Automating Manufacturing Processes

3D printing is reshaping the landscape of modern manufacturing by providing an efficient, automated approach to production. This technology not only streamlines production lines but also reduces costs, enhances efficiency, and offers manufacturers the flexibility to create complex designs with ease. In this article, we’ll explore how 3D printing contributes to automation in manufacturing and its growing impact on the industry.

1. Automating Production Lines with 3D Printing

In traditional manufacturing, production lines often involve complex setups, numerous tools, and labor-intensive processes. 3D printing can simplify these processes by enabling on-demand production with minimal human intervention. By integrating 3D printing into production lines, manufacturers can reduce the time and labor required to produce components and streamline the manufacturing process. This is particularly valuable in industries that require high precision, such as aerospace, automotive, and electronics.

Reduced Downtime: 3D printing minimizes the need for tool changes, allowing for continuous production without interruptions.

On-Demand Parts: Instead of keeping a large inventory, companies can produce parts as needed, reducing storage costs and improving supply chain efficiency.

Flexibility: 3D printing provides the flexibility to create a variety of parts on the same production line, enabling manufacturers to adapt quickly to market demands.

2. Cost Savings in Manufacturing

Using 3D printing for industrial automation can lead to significant cost savings in several ways. From reducing material waste to cutting down on labor costs, 3D printing offers a more economical solution for many manufacturing needs.

Material Efficiency: Traditional subtractive manufacturing wastes a lot of material, as it involves cutting away from a larger piece. 3D printing, however, is an additive process, using only the amount of material required to build the component layer by layer, thus reducing waste.

Reduced Tooling Costs: With 3D printing, there’s no need for molds, dies, or other expensive tooling that traditional methods require. This is especially beneficial for short-run production, where traditional tooling costs would otherwise be prohibitive.

Less Manual Labor: Automating manufacturing with 3D printers reduces the need for human labor in repetitive tasks, allowing companies to reallocate their workforce to more complex, value-added activities.

3. Enhanced Production Efficiency

3D printing technology contributes to production efficiency by speeding up the design-to-production process. Rapid prototyping and quick adaptation to design modifications mean manufacturers can bring products to market faster and respond quickly to changing customer needs.

Rapid Prototyping: 3D printing allows for fast, cost-effective prototyping, enabling manufacturers to test and improve designs in a fraction of the time.

Shortened Lead Times: For custom or complex parts, 3D printing significantly reduces lead times, which can be essential in industries where speed-to-market is critical.

Improved Accuracy: Industrial 3D printers deliver high levels of precision, reducing errors and ensuring parts meet tight tolerances.

4. Industrial Applications of 3D Printing in Automation

3D printing is increasingly used across various industries to automate and improve manufacturing processes. Let’s look at some notable examples:

Automotive: 3D printing is used for producing custom car parts, lightweight components, and rapid prototyping, all of which enhance production efficiency in automotive manufacturing.

Aerospace: Aerospace companies use industrial 3D printers to produce lightweight, complex parts that are often challenging to manufacture with traditional methods. This leads to cost savings and improved fuel efficiency in aircraft.

Medical Devices: From prosthetics to custom implants, 3D printing allows for the rapid production of personalized medical devices, meeting the high precision requirements of the healthcare sector.

5. Future of 3D Printing in Manufacturing Automation

The future of 3D printing in automating manufacturing processes holds significant potential. As technology advances, we can expect even greater integration of 3D printing with other industrial automation tools, such as robotics and artificial intelligence, to create smart, autonomous manufacturing environments.

Smart Factories: Integrating 3D printing with AI and IoT technology can lead to fully automated smart factories, where machines communicate with each other and optimize production in real-time.

Sustainable Manufacturing: With 3D printing, companies can produce only what is needed, reducing waste and energy consumption, which supports the growing demand for sustainable manufacturing practices.

Customized Mass Production: Advances in 3D printing technology will enable manufacturers to customize large quantities of products, combining the efficiency of mass production with the flexibility of customization.

Conclusion

As 3D printing continues to evolve, it’s playing an increasingly important role in automating manufacturing processes. By reducing costs, improving efficiency, and enabling on-demand production, 3D printing is changing how industries operate and innovate. The future promises even deeper integration of 3D printing into automated production lines, unlocking new possibilities for manufacturers across the globe.