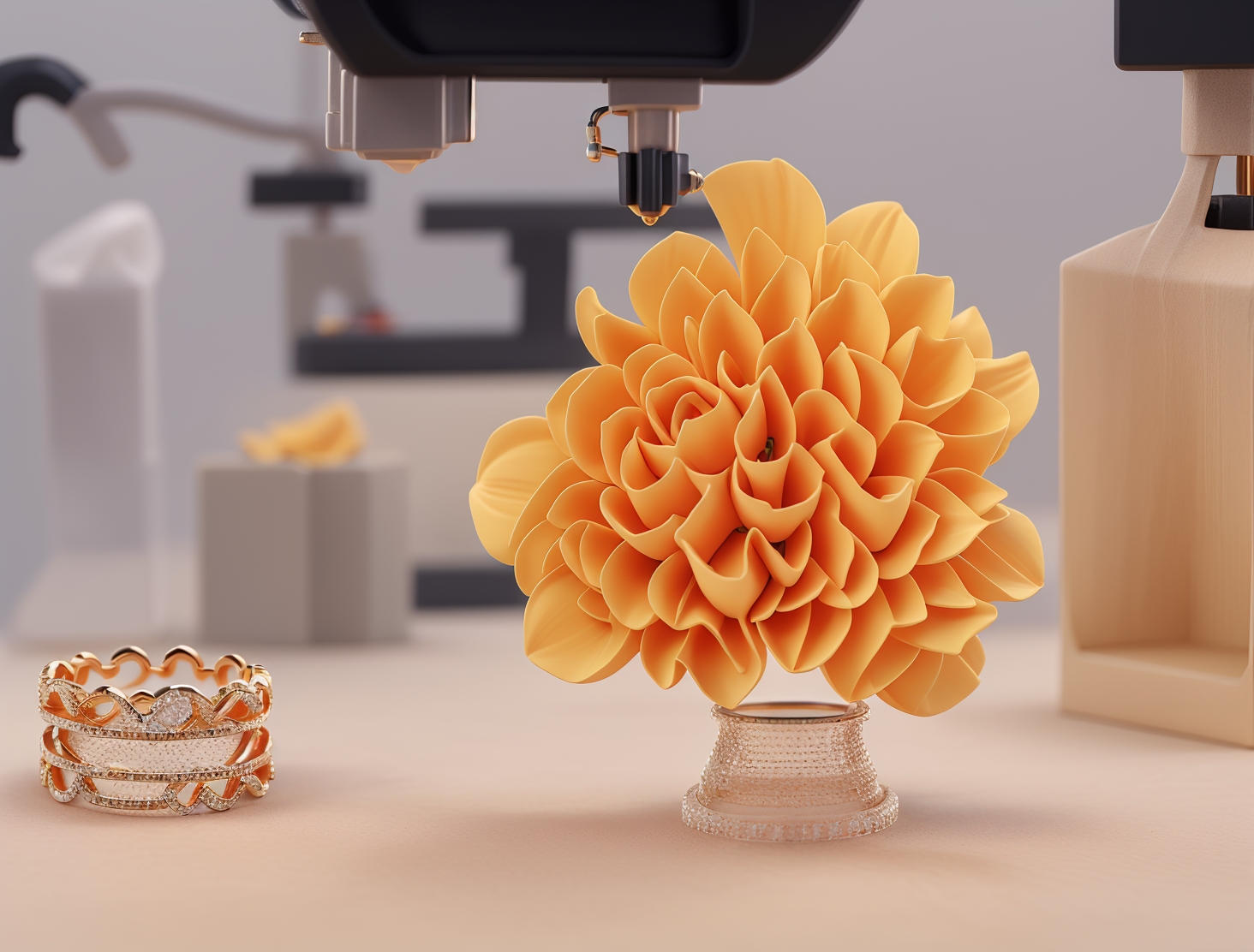

How 3D Printing is Changing the Jewelry Industry

### **How 3D Printing is Changing the Jewelry Industry**

The jewelry industry is experiencing a revolution thanks to **3D printing**. This technology enables **jewelers** to create highly detailed, **custom jewelry designs** with unmatched precision and speed. From intricate engagement rings to bespoke necklaces, **3D printed jewelry** allows designers and manufacturers to push the boundaries of creativity while offering consumers personalized pieces that were once difficult or impossible to create using traditional methods.

#### **The Benefits of 3D Printing in Jewelry Design**

1. **Unprecedented Precision and Detail**: One of the primary advantages of **3D printing** in the jewelry industry is the ability to produce designs with **unmatched precision**. Jewelers can create intricate, delicate details that would be difficult to achieve through handcrafting or traditional manufacturing processes. The **3D printer** can translate complex CAD designs into reality, allowing for intricate geometric patterns and lattice structures that enhance the aesthetic appeal of jewelry.

2. **Customization and Personalization**: **3D printing** allows jewelers to offer fully **customized jewelry** pieces based on individual preferences. Whether it’s a unique engagement ring or a personalized pendant, customers can collaborate with designers to create one-of-a-kind pieces that reflect their style. **3D printed jewelry** also provides a more accessible way for people to get personalized pieces, as it eliminates the time and cost constraints of traditional manufacturing methods.

3. **Faster Prototyping and Production**: Traditional jewelry-making processes can be time-consuming, especially when creating prototypes or custom pieces. **3D printing** drastically speeds up the **prototyping** process, allowing jewelers to quickly test designs and make adjustments before final production. This leads to shorter lead times, enabling faster delivery of finished products to customers. Jewelers can also use **3D printing** to produce master models for casting, significantly reducing production time.

4. **Complex Geometries and Designs**: With **3D printing**, jewelers can explore new realms of design by creating complex geometries that were previously impossible or too costly to manufacture. This opens up opportunities for innovative designs that push the limits of traditional jewelry-making, such as organic shapes, hollow structures, or interlocking components that add uniqueness to each piece.

#### **3D Printing Techniques for Jewelry**

1. **Stereolithography (SLA)**: This **3D printing** technique uses a laser to cure liquid resin into solid layers, creating highly detailed jewelry models. **SLA** is favored for its ability to produce smooth, precise surfaces, making it ideal for creating intricate jewelry prototypes and molds.

2. **Direct Metal Laser Sintering (DMLS)**: For creating **metal jewelry**, **DMLS** is a popular technique. This process involves melting powdered metal using a high-powered laser, layer by layer, to create fully functional metal jewelry pieces. **DMLS** allows jewelers to print in precious metals like gold, silver, and platinum.

3. **Wax Casting with 3D Printing**: Many jewelers combine **3D printing** with traditional wax casting. In this process, a **3D printer** creates a wax model of the jewelry piece, which is then used to create a mold for casting the final metal product. This hybrid approach provides the precision of **3D printing** while maintaining the craftsmanship of traditional jewelry casting.

#### **The Impact on Jewelers and Consumers**

– **Affordability**: **3D printing** reduces material waste and labor costs, making it a cost-effective option for creating custom jewelry. Consumers can enjoy affordable access to unique, personalized jewelry without the high costs associated with traditional handcrafted pieces.

– **Sustainability**: **3D printing** is also more environmentally friendly, as it generates less waste compared to traditional jewelry-making methods, which often involve cutting away large amounts of material. By using **3D printers**, jewelers can create pieces with minimal excess material.

– **Greater Design Freedom**: For both jewelers and customers, **3D printing** opens up greater design freedom. Jewelers can experiment with innovative shapes and structures, while customers can enjoy truly bespoke designs that reflect their personal tastes.

#### **Challenges of 3D Printing in the Jewelry Industry**

While **3D printing** offers many advantages, there are still challenges to overcome. The high cost of some **3D printers**, especially those capable of working with precious metals, can be a barrier for smaller jewelers. Additionally, the quality of the final product is highly dependent on the printer and material used. Jewelers must carefully select the right **3D printing** technology to ensure the quality and durability of their designs.

#### **Conclusion**

**3D printing** is transforming the **jewelry industry** by enabling custom designs, speeding up production, and offering unprecedented precision. Jewelers now have the ability to create intricate, personalized pieces that reflect their clients’ unique styles, while consumers can enjoy affordable access to custom jewelry. As **3D printing** technology continues to advance, its role in **jewelry design** will only grow, making it a critical tool for the next generation of jewelers.