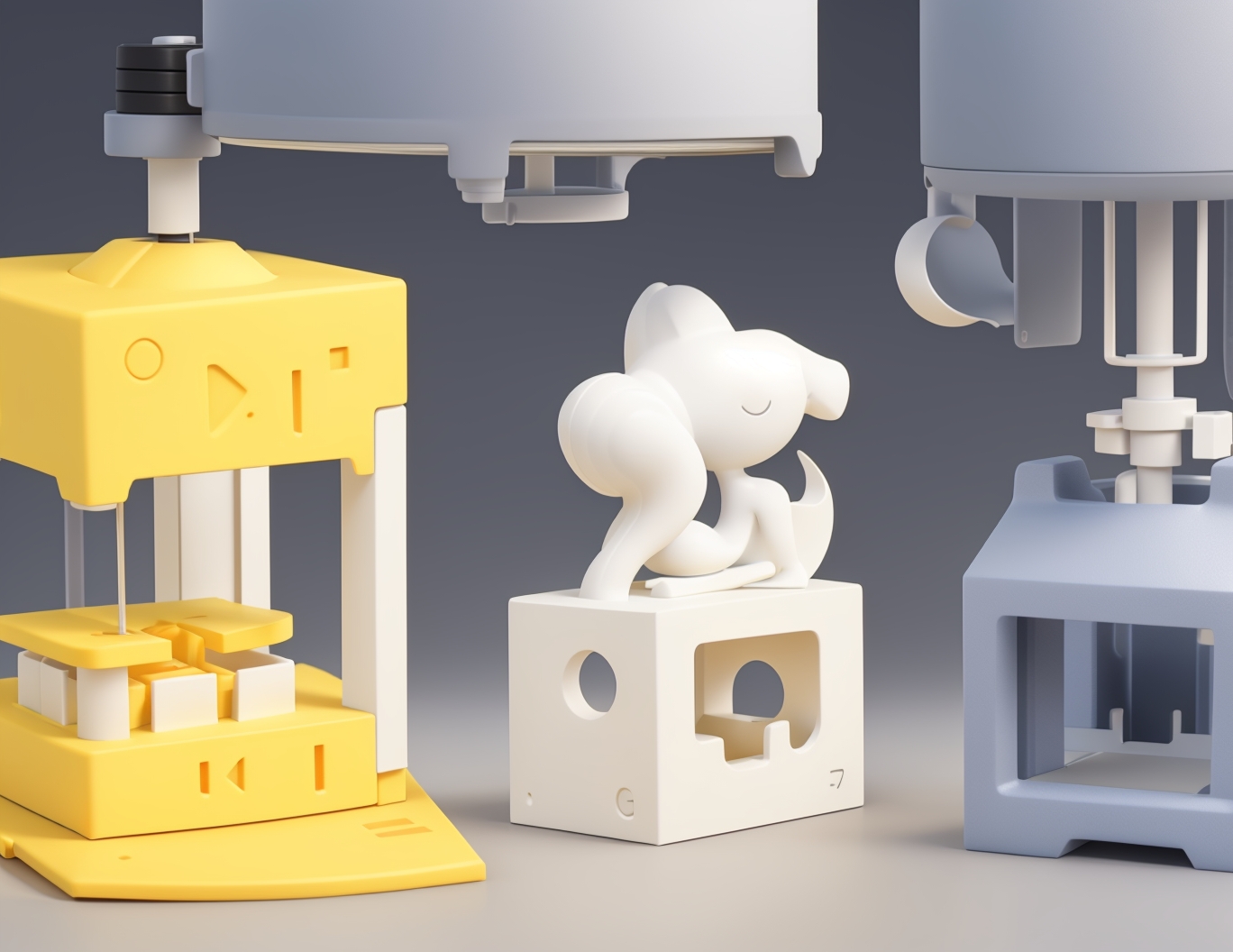

Creating Functional Prototypes with 3D Printing

Creating Functional Prototypes with 3D Printing

Description: How to use 3D printing to create functional prototypes for product testing and development, covering materials, durability, and design considerations.

Keywords: 3D printing prototypes, functional 3D printed parts, product testing with 3D printing

Introduction

3D printing has revolutionized the process of product development by enabling rapid creation of functional prototypes. These prototypes allow designers and engineers to test their products’ form, fit, and function before moving to mass production. This guide explores the best practices, materials, and design strategies for creating functional 3D printed prototypes.

1. Why Use 3D Printing for Functional Prototypes?

Speed: Shortens development cycles by quickly turning digital designs into physical models.

Cost-Effective: Reduces costs compared to traditional methods like injection molding.

Customization: Easily makes design adjustments to fit specific requirements.

Material Variety: Offers access to durable materials suitable for functional testing.

2. Choosing the Right 3D Printing Technology

Common Technologies for Functional Prototypes:

FDM (Fused Deposition Modeling): Great for large and sturdy prototypes but may lack fine detail.

SLA (Stereolithography): Ideal for high-detail prototypes, though less durable than FDM.

SLS (Selective Laser Sintering): Provides excellent durability and is perfect for complex geometries.

3. Selecting the Right Material

Popular Materials for Functional Prototypes:

PLA: Easy to print and eco-friendly but lacks strength for functional testing.

ABS: Durable and impact-resistant, suitable for mechanical parts.

PETG: Combines flexibility and strength, making it ideal for functional components.

Nylon: Highly durable and wear-resistant, perfect for moving parts.

TPU: Flexible material for prototypes requiring elasticity.

Material Selection Tips:

Use stronger materials like ABS or Nylon for mechanical testing.

For aesthetic prototypes, opt for PLA or resin-based materials.

Consider heat-resistant materials for testing prototypes in high-temperature environments.

4. Designing for Functionality

Key Design Considerations:

Wall Thickness: Ensure walls are thick enough for durability but not excessive to reduce material use.

Tolerances: Account for material-specific shrinkage and dimensional tolerances.

Supports: Design parts to minimize overhangs and reduce the need for support structures.

Tips for Optimizing Designs:

Use fillets instead of sharp corners to enhance strength.

Add reinforcement ribs to increase stiffness without significant weight gain.

Validate your design with 3D CAD simulation tools to identify potential stress points.

5. Post-Processing for Enhanced Functionality

Improving Prototype Quality:

Sanding and Smoothing: Remove surface imperfections for a refined finish.

Painting and Coating: Apply protective layers for added durability.

Assembly: Combine multiple parts into a functional prototype for testing.

6. Testing and Iteration

Prototype Testing:

Mechanical Testing: Check for strength, flexibility, and load-bearing capacity.

Functional Testing: Ensure moving parts operate as intended.

Environmental Testing: Test the prototype under conditions like heat, moisture, or stress.

Iterative Design:

Use feedback from initial testing to refine your design.

Modify CAD files and reprint updated versions until the desired functionality is achieved.

7. Examples of Functional Prototypes

Consumer Electronics: Test-fitting enclosures for devices like phones or tablets.

Automotive Parts: Validate components like brackets, vents, or housings.

Medical Devices: Create custom prosthetics or surgical instruments for trials.

Conclusion

3D printing prototypes empowers businesses to streamline product development, enabling faster and more affordable testing and iteration. By selecting the right materials, printing technology, and design strategies, you can produce functional 3D printed parts that meet the demands of real-world testing. Embrace 3D printing to innovate and bring your product ideas to life efficiently.