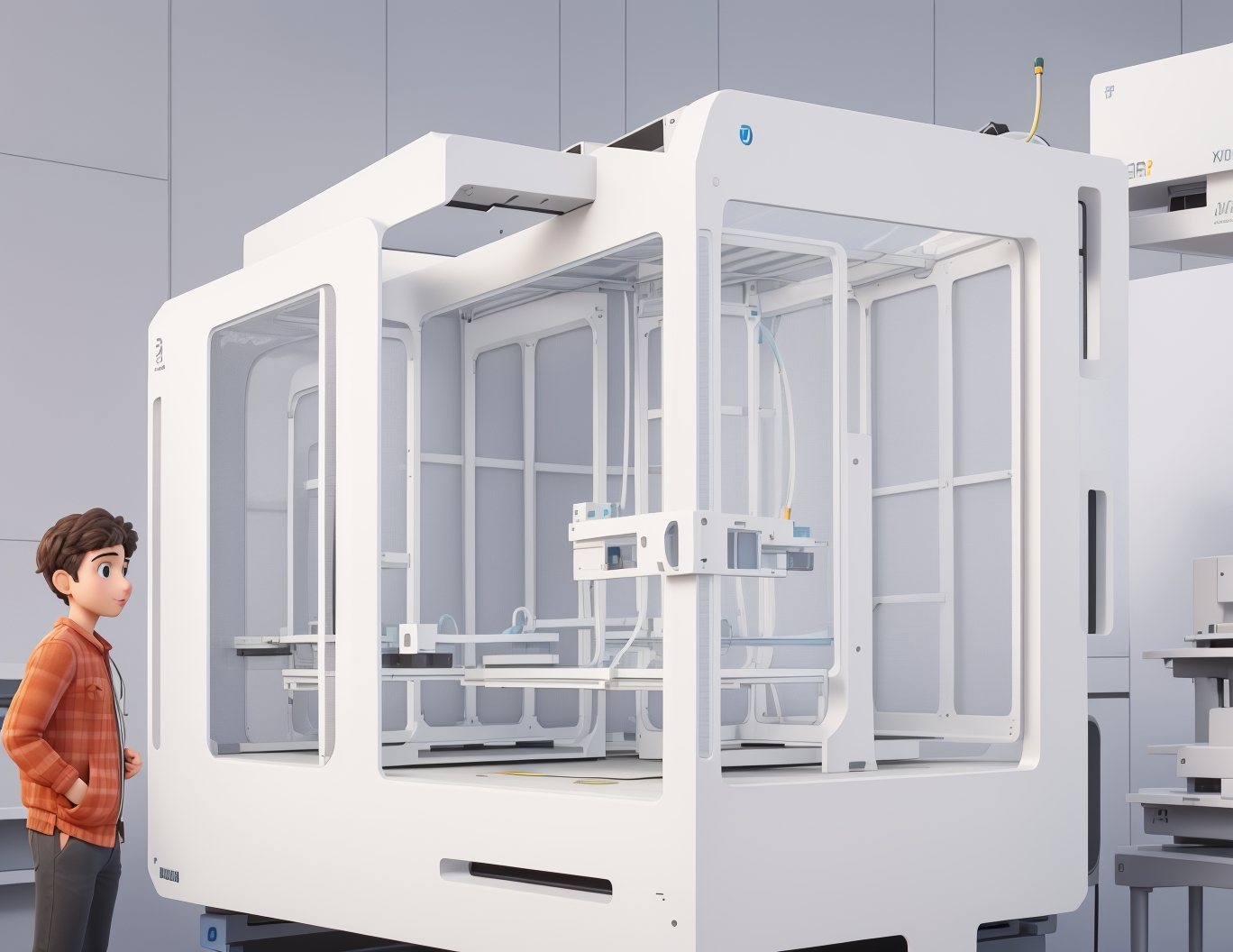

Scaling Up: Large-Format 3D Printing and Its Applications

Scaling Up: Large-Format 3D Printing and Its Applications

As 3D printing technology advances, the demand for large-format 3D printers has grown, with industries increasingly exploring ways to use these machines for creating bigger prototypes, components, and even full-sized structures. In this article, we will introduce large-format 3D printing, discuss its capabilities, and examine applications in industries that benefit from large-scale additive manufacturing.

1. What is Large-Format 3D Printing?

Large-format 3D printing refers to the use of printers with an extended build volume capable of producing objects much larger than those created by standard 3D printers. These machines often require specialized technology and materials to ensure stability and precision on a larger scale, and they cater to sectors like construction, automotive, and aerospace that require large components or prototypes.

2. Capabilities of Large-Format 3D Printers

Large 3D printers offer unique capabilities that make them essential for certain industries:

Extended build size: These machines can print objects measuring several feet or meters, ideal for creating large prototypes and components.

High-strength materials: Many industrial 3D printers support high-strength materials, including metals and durable polymers, which are essential for structural applications.

Precision at scale: Despite their size, advanced large-format printers maintain a high level of precision, ensuring the structural integrity and accuracy needed for functional components.

Reduced assembly needs: With large-format 3D printing, parts that would traditionally be printed in sections and then assembled can be produced as a single piece, simplifying production and reducing potential weak points.

3. Applications of Large-Format 3D Printing

Large-format 3D printing technology has unlocked applications across several industries where size and durability are essential.

Construction: Large-scale 3D printers are being used to print entire buildings or building components, with concrete and composite materials. This process reduces material waste and labor costs, while 3D printed structures can be created in a fraction of the time compared to traditional construction.

Automotive industry: Automakers use large-format 3D printers to create full-size prototypes and custom parts. Rapid prototyping with large 3D printers accelerates product development, enabling faster design iterations.

Aerospace: The aerospace sector has adopted large-format printing to produce lightweight, durable parts that withstand extreme conditions. Large 3D printed components like fuselage sections and engine parts can be customized for each aircraft.

Marine industry: Large 3D printers are also used in the marine industry to produce hulls and other substantial parts, enabling the creation of complex, weight-optimized designs that are difficult to achieve with traditional manufacturing.

Furniture and interior design: Designers are using large-format 3D printing to create unique furniture pieces, sculptures, and architectural elements, as it allows for highly customized, intricate designs on a bigger scale.

4. Benefits of Large-Format 3D Printing

The benefits of large-scale 3D printing extend beyond just the ability to produce larger parts:

Cost efficiency: By reducing the need for molds, tools, and assembly, large-format 3D printing can lower production costs, especially for small-batch or custom parts.

Design flexibility: This technology allows for complex, customized designs that are often impossible to achieve with traditional methods.

Sustainability: Large-scale 3D printing can be more environmentally friendly, as it reduces material waste by only using what’s necessary for the build.

Reduced lead times: Industries using large 3D printers can reduce production times significantly, speeding up development and getting products to market faster.

5. Challenges in Large-Format 3D Printing

While large-format 3D printing offers significant advantages, it also presents some challenges:

High initial cost: Large-format 3D printers are generally more expensive than standard models, making them a significant investment.

Material limitations: Not all materials are suitable for large-scale printing, as some may not provide the strength and durability required for structural components.

Technical expertise: Operating large-format printers often requires specialized knowledge, and companies may need to train staff or hire experienced operators.

Space and infrastructure requirements: Large 3D printers require ample space and may need additional infrastructure, such as improved ventilation, material storage, and specialized power sources.

Conclusion

Large-format 3D printing is proving to be a transformative technology across various sectors, enabling the production of large components and prototypes that were once time-consuming and costly to create. As technology continues to evolve, large 3D printers will likely become more accessible, pushing the boundaries of what’s possible in industrial 3D printing. By understanding the capabilities, applications, and challenges of large-format 3D printing, companies can make informed decisions about integrating this powerful tool into their production processes.