3D Printing Replacement Parts: A Game Changer for DIY Repairs

3D Printing Replacement Parts: A Game Changer for DIY Repairs

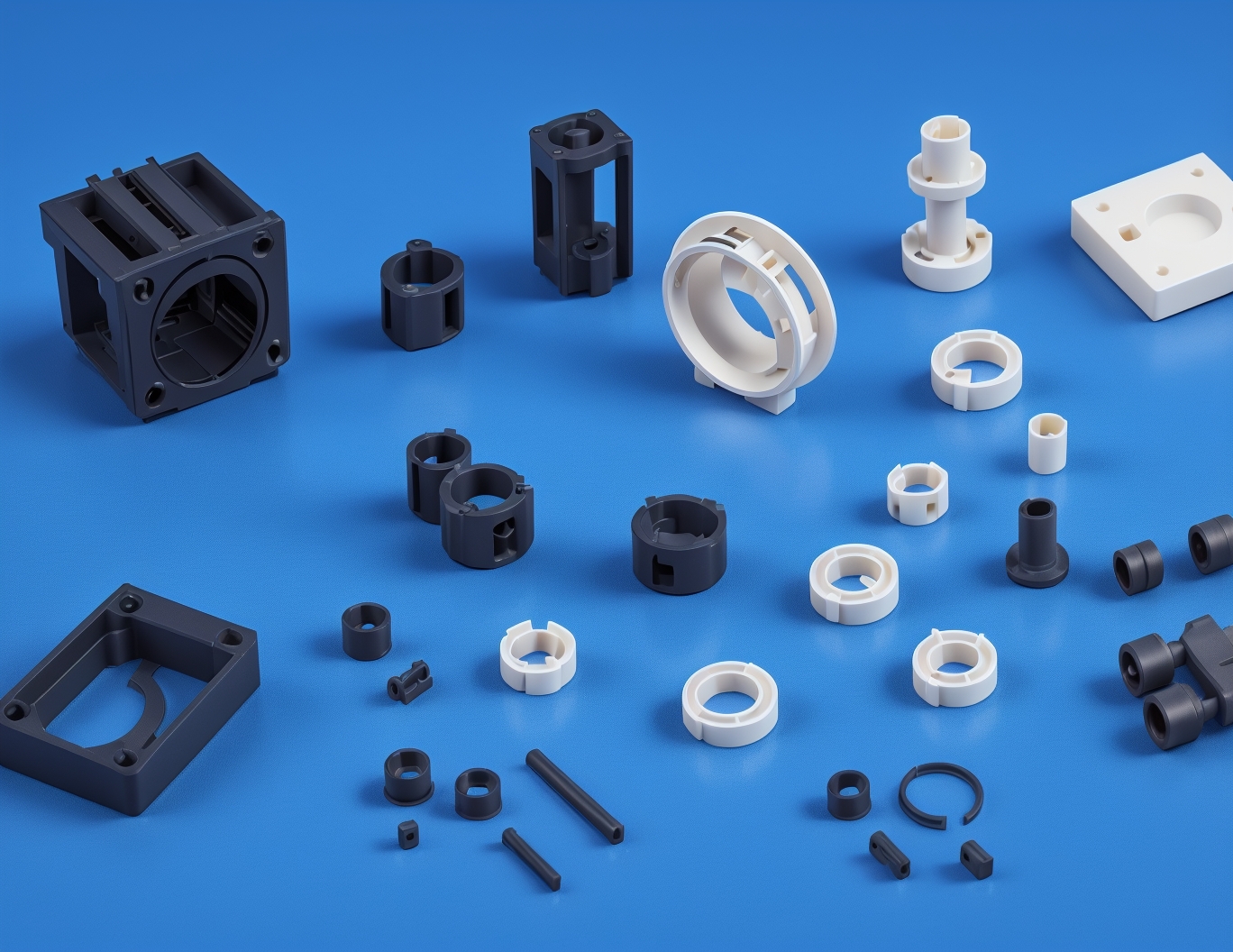

As 3D printing technology becomes more accessible, it’s revolutionizing the world of DIY repairs by allowing people to create replacement parts for household items, electronics, and more. Instead of searching for discontinued parts or paying for costly repairs, users can simply design and print what they need. In this article, we’ll explore how 3D printing empowers DIY enthusiasts to tackle repairs on their own.

1. Why 3D Printing is Ideal for DIY Repairs

3D printing has opened up new opportunities for those interested in DIY projects, particularly when it comes to fixing gadgets and household items. The ability to create custom parts and components makes it easy to replace broken parts and extend the lifespan of everyday products.

Convenience: Rather than searching for rare parts, users can design or download models for replacement parts and print them at home or through a local service.

Cost Savings: 3D printed parts are often cheaper than purchasing replacements from original manufacturers, which can be particularly useful for older or discontinued products.

Customization: 3D printing allows for customizing parts, which means users can improve or adapt the replacement to suit their specific needs or enhance durability.

2. Common Items That Can Be Repaired with 3D Printed Parts

Many household items and gadgets benefit from 3D printed repairs, saving money and reducing waste. Some common examples include:

Appliance Handles: Handles on ovens, refrigerators, and washing machines frequently break. 3D printing allows users to create exact replacements that match the original.

Small Electronics: Many small electronics, such as remotes, keyboards, or controllers, often require small replacement parts that are hard to find, which can be printed with ease.

Toys and Games: Missing pieces or broken parts in toys and board games are easily replaceable through 3D printing, especially when the manufacturer no longer provides replacements.

Furniture Hardware: Replacement hinges, knobs, and connectors for furniture can be printed, providing quick and affordable solutions for worn-out parts.

3. How to Get Started with 3D Printing Replacement Parts

Getting started with DIY repairs using 3D printing is straightforward, with options available for both beginners and experienced users.

Find or Design a Model: Websites like Thingiverse, MyMiniFactory, and GrabCAD offer a wide range of 3D models for replacement parts. If the part you need isn’t available, 3D modeling software like Tinkercad, Fusion 360, or Blender can help you create a custom design.

Select the Right Material: Choosing the right material for the part is crucial. For durable items, ABS or PETG can provide the necessary strength. For decorative or non-load-bearing parts, PLA is a good, eco-friendly option.

Optimize Print Settings: Adjust settings like layer height, infill density, and print speed to ensure the part’s quality and durability. For parts under stress, using a higher infill density or stronger materials can prevent future breakage.

4. Advantages of 3D Printed Replacement Parts for DIY Repairs

Using 3D printed replacement parts offers several key advantages that make it an attractive option for home repairs and gadget fixes.

Sustainability: By creating replacement parts on demand, users can keep items in use longer, reducing the waste that comes with disposing of broken products.

Self-Sufficiency: With 3D printing, DIY enthusiasts have the tools to fix things independently, eliminating the reliance on hard-to-find or expensive spare parts.

Accessibility: 3D printing services are widely available, so even those without a 3D printer can access printed parts, making DIY repairs possible for more people.

5. Challenges and Tips for Successful DIY Repairs with 3D Printing

While 3D printing is a powerful tool for DIY repairs, it does come with its challenges. Here are some tips to ensure success:

Get Accurate Measurements: Accurate measurements are essential for creating parts that fit. Using digital calipers can help you get precise dimensions of the original part.

Choose High-Quality Models: Look for models with good reviews or those created by experienced designers to avoid issues with fit and functionality.

Practice Patience: Some parts might take a few tries to get right, especially if you’re adjusting dimensions or modifying the model. Be prepared to iterate and improve your design for the perfect fit.

6. The Future of 3D Printing in DIY Repairs

As 3D printing technology advances, its role in DIY repairs will only expand. Upcoming improvements in materials and printer capabilities will make it possible to print stronger, more resilient parts that can handle greater wear and tear. This future trend promises even greater accessibility and efficiency in home repairs, further empowering individuals to take on repair projects with confidence.

Conclusion

3D printing is transforming the world of DIY repairs by providing a convenient, cost-effective, and customizable way to print replacement parts for everyday items. Whether you’re fixing a household appliance, revamping a favorite gadget, or replacing a toy part, 3D printing offers a sustainable solution that puts repair power in your hands.