3D Printing Prototyping: From Idea to Product

### **3D Printing Prototyping: From Idea to Product**

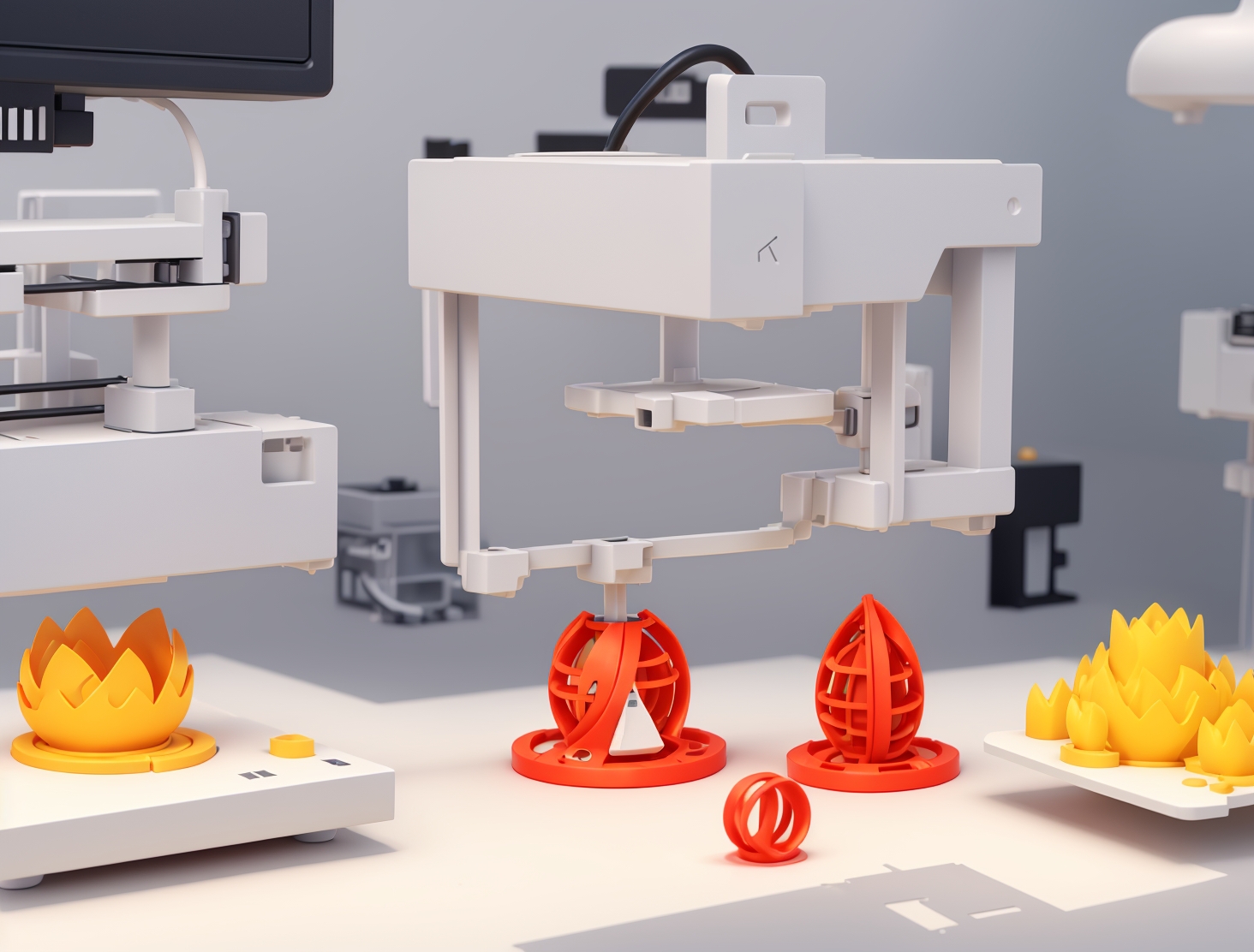

**3D printing** has transformed the way businesses and designers approach **prototyping**, significantly reducing both time and costs. This technology allows for the creation of accurate, functional models directly from digital designs, making it an essential tool for **rapid prototyping**. In the past, developing a prototype involved a lengthy process, including designing, fabricating molds, and outsourcing production. Now, with **3D printing for prototyping**, the entire process is streamlined, offering businesses the ability to test, iterate, and refine their products in record time.

#### **The Benefits of 3D Printing for Prototyping**

1. **Speed**: One of the key advantages of **3D printing** in **product development** is the ability to produce prototypes quickly. Traditional prototyping methods can take weeks or even months to deliver a functional model. However, **rapid prototyping** with **3D printing** can shorten this timeline to just a few hours or days, depending on the complexity of the design.

2. **Cost Efficiency**: The cost of creating a prototype using conventional methods is often high due to the need for specialized tools and molds. **3D printing for prototyping** eliminates these extra expenses, making it more affordable to create multiple iterations of a design. This makes it ideal for startups and smaller businesses looking to test concepts without the high overhead costs associated with traditional manufacturing.

3. **Iterative Design**: With **3D printing**, it’s easier to make design changes on the fly. Designers can quickly adjust digital files and print new versions of their models. This iterative process allows for more frequent testing and refinements, which is crucial for **product development**. Companies can perfect their prototypes before committing to mass production, ensuring better end products.

4. **Complexity of Design**: **3D printing** excels at producing highly detailed and complex shapes that would be difficult or impossible to achieve with traditional manufacturing techniques. This opens the door for innovative designs in industries such as aerospace, healthcare, and consumer electronics. For instance, engineers can create intricate internal structures or moving parts in a single print.

#### **How 3D Printing Has Changed Product Development**

In the world of **product development**, the ability to create a working prototype quickly is invaluable. **3D printing** allows designers to visualize their ideas in a tangible way and identify design flaws early in the process. By leveraging **3D printing for prototyping**, companies can speed up their development cycles, get products to market faster, and reduce the financial risks of launching a new product.

#### **Applications of 3D Printing in Prototyping**

– **Consumer Electronics**: Brands can quickly produce and test new gadget designs, tweaking features to meet consumer needs.

– **Healthcare**: Surgeons use **3D-printed** models for preoperative planning, while medical device companies prototype new tools and equipment.

– **Automotive**: Car manufacturers rely on **rapid prototyping** to develop parts that are lightweight, functional, and highly optimized for performance.

#### **Conclusion**

**3D printing for prototyping** has become a cornerstone of modern **product development**, offering speed, cost savings, and design flexibility. As the technology continues to evolve, its role in creating innovative products and reducing time to market will only grow. By embracing **rapid prototyping**, businesses can remain competitive in a fast-paced market, delivering high-quality products that meet consumer demands.